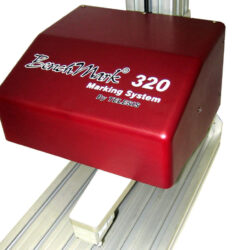

Description

- Easy to operate

- Automatic compensation for variation in work piece diameters.

- Rigidly fabricated, reinforced steel frame.

- Stress relieved.

- Can mark round work piece up to 200 mm diameter.

- Can mark flat work piece up to 170 mm thickness.

- Open back permits marking of long bars.

- Serial numbers can be marked with automatic indexing.

- Can make up to 4 lines of 6 mm characters, or 8 lines of 3mm characters.

- Ample daylight permits extensive use of fixturing and tooling for almost all shapes and sizes of components.

- Electrically – controlled hydraulic operations: hydraulic cylinders operate table and marking die slide.

- Table pressure controls depth of mark : ensuring uniform depth.

- One master foot-pedal control for operating table and die slide cylinders in proper sequence.

- Specially designed cylinder fitted with hardened bearing.

- Die slide moves on hardened plate with rollers for precision and long life.

“COMPONENTS THAT CAN BE MARKED Shock Absorbers, Flanges, Elbows, Bends, Mortar Barrels, Gears, Fuses, Pistons, Couplings, Railroad Bearings, Shells, Axles, Propeller Shats, Rock Drills, Magneto, Lock Body.

so easy to operate ! Takes just a few minutes on the machine to know to operate it!

ALSO AVAILABEL AGAINST SPECIFIC ORDERS : SPECIAL PURPOSE MACHINES WHEREIN

BRADMA DIEHARD TOOLINGS (Interchangeable Steel Types, Stamp Marks and Holders)